Automatically the right circuit symbol: ECLASS and AmpereSoft create the future of computer aided engineering

Networking and communication as well as the interaction of various actors and components are almost standard in many areas today. Not so in electrical engineering. Although seamless digital processes should be the norm here in the sense of Industry 4.0, there are still “white spots” on the engineering map that can only be overcome by human manual labour. This includes the creation of circuit symbols for circuit diagrams. Thanks to ECLASS 13, however, this work is now a thing of the past.

One of the biggest challenges in the field of electrical engineering today is the incompatibility of the systems used. A smooth exchange of information, which has long been the norm elsewhere, has only been partially successful here so far. The reason: the various solutions were developed independently of each other and thus have their own logics when it comes to reading out data and interpreting it. But the market demands forward-looking answers – there is pressure to act.

ECLASS 13 automates the creation of circuit symbols

The solution are standards like ECLASS, which offer opportunities and benefits for all parties involved. That is why AmpereSoft has been engaged in the further development and establishment of the standard for master data and semantics for many years. We were also actively involved in the work for ECLASS 13 and are pleased to have reached a real milestone for the smooth engineering process with the new version. The tedious manual creation of circuit symbols for the circuit diagram of a plant is now a thing of the past.

With ECLASS 13, automated symbol creation using solutions such as the AmpereSoft ToolSystem is being introduced across the board. This benefits all parties involved in the engineering process: CAE providers, component manufacturers and, last but not least, the users. They are no longer responsible for creating the circuit symbols themselves in the correct form and thus save valuable time. For the software companies, there is no longer any need to request the relevant data from the respective component manufacturers in order to provide their own users with a good basis for their work. The manufacturers themselves only need to output a DXF symbol so that their products can be used smoothly in the respective planning tools.

How the automated circuit symbol creation works

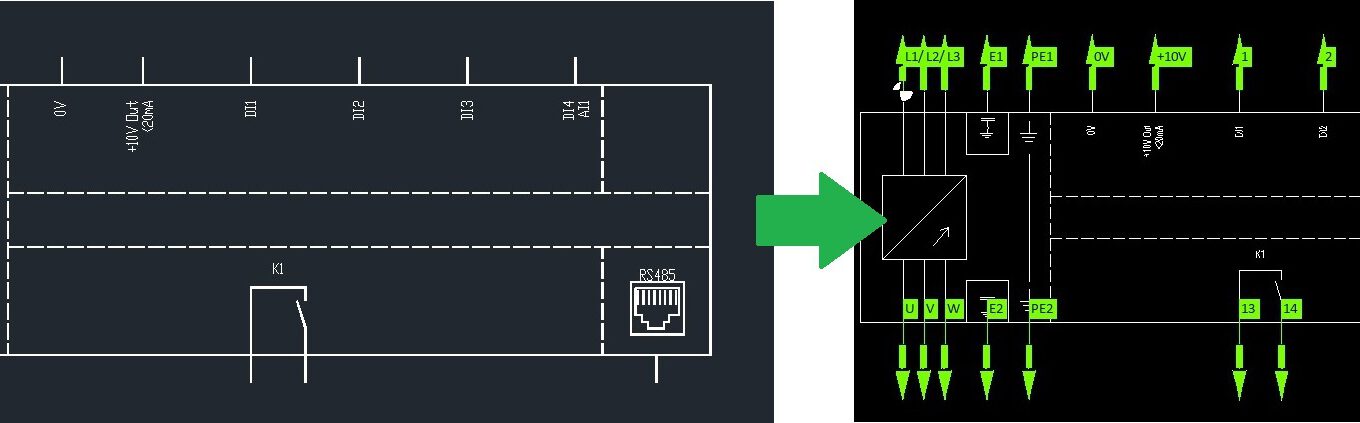

The automated generation of circuit symbols is based on the combination of a drawing in DXF format and the data stored in ECLASS. The DXF format has the benefit that it is supported by almost all systems and is thus ideally suited for transporting the circuit symbol to a further-processing system. Every relevant solution can read DXF drawings without any problems. However, the drawing alone cannot be used in the circuit diagram without logical information, for example on connections or the mode of operation.

This logical information is stored in ECLASS: Is a connection an input or output, is it digital or analogue? In which position is a connection located and in which direction does it point? Modern solutions such as MatClass, the material and performance catalogue system integrated in our ToolSystem, can easily obtain this data from ECLASS. In combination with the drawing in DXF format, all the information required for a fully-fledged circuit symbol exists.

Automatic and standard-compliant

When creating circuit symbols, the greatest care must be taken because there are various standards that must be complied with. It is specified in detail how documents and symbols in electrical engineering must be designed. The line width, the distance to the module or the distances between the connections: all this is included in a circuit symbol in a standardised form. When working on ECLASS 13, therefore, care was taken to take the applicable specifications into account in the automated creation of symbols, so that neither planners nor manufacturers have to worry about them.

With ECLASS 13 and correspondingly powerful software such as our ToolSystem, ready-made and fully usable circuit symbols for digital circuit diagram creation are thus created without human assistance. Automation is also advancing in other areas: at the Hannover Messe, for example, it was possible to see for the first time how the robot-assisted wiring of switch cabinets works, which inevitably leads to the question of how long human-readable circuit diagrams will be needed at all. Even today, they are mainly used for control and documentation; the actual realisation has long since ceased to rely on drawn plans – be they analogue or digital.

Standards as a basis for future progress

When exactly this next evolutionary step of Industry 4.0 will occur is difficult to say today. What is certain, however, is that standards such as ECLASS will continue to form the basis for all important processes in the future, and probably even more so than today. One more reason to get involved in the further development of ECLASS.