Common basis for engineering processes: No problem with the ECLASS standard

ECLASS: This is a cross-industry, standard-compliant and at the same time open standard for master data and semantics. It can be used to describe and classify goods and services worldwide, so that Industry 4.0 or the Internet of Things are within reach. But what is it about the standard and what concrete advantages does it offer for industry and engineering processes?

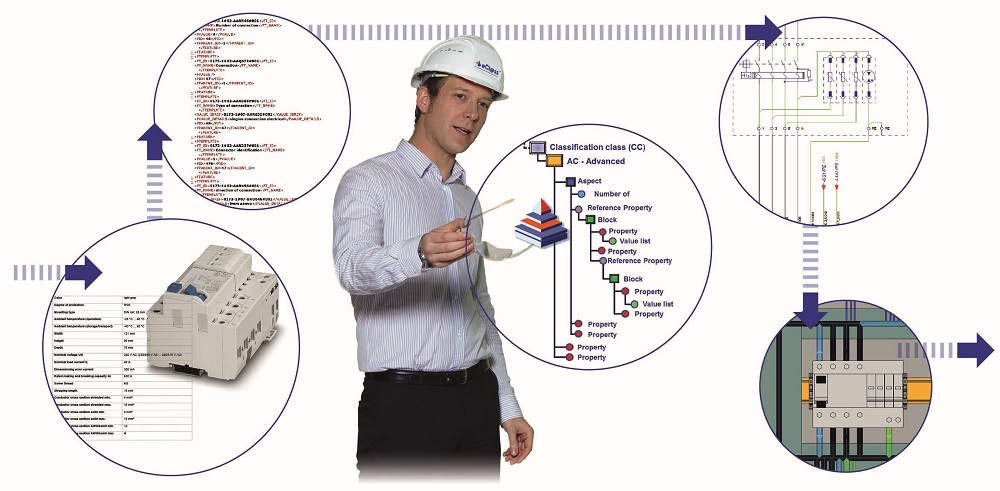

39 search areas, 45,000 product classes, 19,000 clearly described characteristics and four classification levels: With them, product data can be structured and described in detail across national borders and languages. No wonder, then, that the ECLASS standard has established itself worldwide in recent years and that numerous companies benefit from it. But why is such a standard necessary and why aren’t the company’s own internal description mechanisms sufficient to classify its own products?

New possibilities thanks to ECLASS

Industry 4.0, i.e. the networking of man, machine and product, requires communication between all three parties. Information on individual components must be exchanged constantly, for example to determine which machine will carry out the next production step and which route the workpiece to be processed will take to get there. Requirements have to be made and understood, and problems in the process have to be identified and solved if possible.

For this communication to succeed across industries and suppliers, a common language is needed: a standard. With ECLASS, all data is machine-readable and the characteristics are unambiguous, making the format ideally suited to meet the challenges of Industry 4.0.

These already start with the engineering process. When planning a switch cabinet, all protection parameters must be known. If the data of the individual components are specified in ECLASS, this results in a significant relief for the designers. Instead of collecting all data manually from catalogues and digitising and preparing it for the tool currently in use, fine-granular and detailed information is available and can be used immediately. ECLASS is ISO-compliant and thus ensures a standard-compliant description.

Detailed classification

Each product and service described in ECLASS can be mapped with an eight-digit code. This contains the product class, specific characteristics and a classification to make the information easier to find. The codes are comprehensible and unambiguous across all sectors, as the characteristics are always named in the same way. In order to guarantee the greatest possible topicality, the standard is further developed through annual releases. Users can support this process by passing on their experience in the practical use of the standard to the ECLASS working groups. There they will be incorporated into the development of the next version.

Additional identifiers such as the supplier name or a special brand name can be attached to a code in order to transport information that goes beyond the master data. Thanks to the open architecture, it is not necessary to throw all the systems used in the company overboard when introducing the standard. Rather, the classification system can be adapted to the company’s own systematics. This prevents media discontinuities, overcomes barriers and eliminates friction losses.

Two views for different tasks

ECLASS is available in two views that can be merged at any time. The ECLASS BASIC variant is characterised by flat feature bars. It is particularly suitable for areas such as sales, purchasing or controlling. All data is human- and machine-readable. Another advantage is the simple implementation.

A flexible multidimensional feature structure, on the other hand, is inherent in the ECLASS ADVANCED variant. The data is mainly machine-readable. The more complex implementation pays off in engineering processes when the designers can fall back on a common basis and all master data can be clearly identified without tedious searches. The output format here is an XML file.

Common to both views is the hierarchical structure, which is divided into four elements:

- Subject areas

- skin groups

- groups

- Classes

Order is half the battle

Companies that maintain their data according to ECLASS benefit from a better exchange with customers and partners. This significantly strengthens their competitive position. Simplified processes save time and reduce costs, while at the same time increasing profits by opening up new sales potential, for example through electronic catalogues. Last but not least, the standardised data ensure continuous processes and thus improved performance.

For the designers, on the other hand, it is crucial that as many companies as possible use ECLASS and that the standard becomes more established. This is the only way to realise unambiguous designations and a consistent common database across the board. The data needed for an engineering process are particularly complex. ECLASS ADVANCES therefore offers four structural elements for a meaningful subdivision:

- Block

- Aspect

- Cardinality

- Polymorphism

Clarity and best data availability

The block provides better clarity by bringing together thematically related characteristics and collecting them under one name. This makes it possible to describe the specific characteristics of a certain product via a block instead of realising this via numerous individual characteristics that have to be searched for individually. In a block, the necessary information can be found quickly and easily in one place.

This structural element is continued via the aspect, a special variant of the block. Here, different characteristics and also blocks can be brought together. However, this is not about product-specific characteristics of a good, but about the context of a product. Thus, information on connections or on construction is given, as it is important for the engineering process.

Cardinality also ensures simplification, especially when it comes to designing large systems or entire production lines. If there are several identical components, the effort to provide each with exactly the same characteristics would be enormous. Therefore, it is possible to reproduce blocks by means of the multiplication element cardinality. They can be stored in several places and can therefore be called up several times.

It is not necessary to view all the characteristics of a product at every point in the planning or development process. Rather, it is advantageous if exactly the data that is needed at the corresponding point in time is available. This is where polymorphism comes into play. With this element, users can decide which characteristics of a block are to be displayed. On the one hand, this avoids redundancy, on the other hand, all the necessary details of the product characteristics are available at the right time.

Conclusion

The industry standard ECLASS provides a detailed and clear description and classification of products. Users can view all important characteristics of goods across industries and countries. Ambiguities caused by company-internal description mechanisms that differ in the meaning of individual characteristics are thus a thing of the past. Especially in the engineering process, this leads to simplifications that are also reflected in significant cost and time savings with increased productivity. The advantages become even clearer the more companies work with the standard and the more it becomes established.