Product data standard ECLASS 11.0: Innovations and advantages of the new version for CAE

Open product data standards such as ECLASS Advanced are becoming more and more important because they are a prerequisite for Industry 4.0 to become reality. Version 11.0 of the standard represents the largest further development to date. Reason enough to take a closer look at the most important advantages and innovations with regard to CAE.

Since the foundation of ECLASS e. V., the standard has been continuously developed. A new version of ECLASS is published annually. The new version 11.0 stands out from its predecessors in that it contains the most extensive innovations since the launch of the first version.

These innovations bring far-reaching advantages for CAE. Two examples, which will be explained later in the text, make this particularly clear: With version 11.0, engineering data for protection parameters are now available. In addition, the possibility of describing products functionally has been added. For designers, both further developments mean a noticeable relief in the planning of switchgear.

Functions can be described

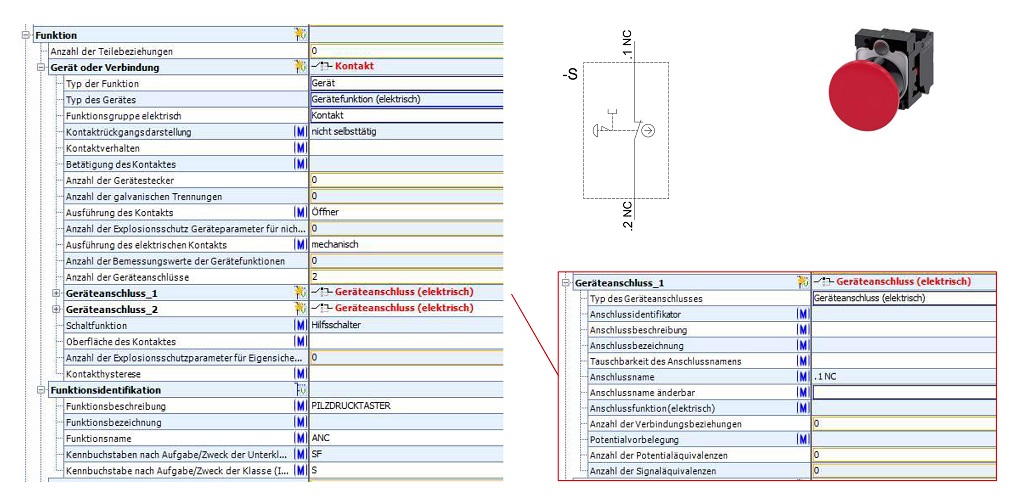

The physical sizes of components are, of course, important information when creating circuit diagrams. However, the fact that ECLASS 11.0 can now also describe the functions of products opens up completely new possibilities for CAE. With software support from the AmpereSoft ToolSystem, important advantages can be achieved from the ECLASS function descriptions, especially with regard to saving time when creating circuit diagrams. This enables the automated generation of circuit symbols, which can then be easily inserted into the circuit diagram. This applies to both standardised and non-standardised functions. Previously, designers had to more or less take care of procuring the corresponding symbols themselves. In some cases, they even had to create them themselves at great expense. Quite simply because, for reasons of economy, it is often not possible for manufacturers to supply all the required symbols for all CAE systems on the market.

ECLASS supports software-based network calculation

The description of the protection parameters is part of the indispensable information when the network calculation of a switchgear is to be carried out and in order to ensure the network protection by selectivity.

For software-supported network calculations, for example, a lot of fine-grained technical information is needed in digital form. Researching this information and preparing it for the corresponding tools requires an enormous amount of manual effort – especially if the data originally comes from catalogues or other documents and must first be digitised. Automating the processes in this way is not possible.

Engineering data is extremely diverse and complex. Describing them in a standardised way is a major challenge. This is because the data varies due to technical dependencies or results from normative requirements of type test reports. They are usually represented as graphs, which is why they cannot be described in a flat feature structure and have so far been provided individually by the product manufacturers.

Multidimensional data structures

With the help of ECLASS, protection parameters can now be described specifically and in detail – in a language-neutral, machine-readable, industry-independent and unambiguous manner. No other product data standard is able to dynamically map multi-dimensional data structures. To achieve this, information in ECLASS is divided into structural elements such as block, aspect, cardinality and polymorphism. If a block is to be created, users must form a so-called reference feature.

To ensure a better overview, characteristics that belong together are divided into blocks under a certain name. If they were listed on a single level, this would result in a long chain consisting of features. And each time a new feature is added, this chain would even grow. Another advantage of blocks is that they can be reused in different places.

Aspect, cardinality and polymorphism

The collection of thematically related features and blocks is summarised under the term aspect. An example of this is the aspect “CAx connections and functions”. Here, detailed information such as type, position and usable conductor cross-sections of a product can be found. In addition, the functions are described to enable the quickest possible use in engineering and automated production.

The individual blocks can be multiplied as needed. This further possibility of ordering the characteristics of a class is called cardinality. Suppose a production line is equipped with six identical gripper arms whose characteristics are combined in one block. In this case, it is sufficient to set the reference characteristic “Number of gripper arms” to “6”: The corresponding block would be retrieved six times in this case.

Polymorphism – the “multiformity” – offers the possibility in ECLASS to use different blocks for the description and this depending on a special feature value. For example, specifically composed characteristics (blocks) are used for electrical, pneumatic or optical connections.

ECLASS 11.0 brings Industry 4.0 one step closer

Already with the first publication of the ECLASS standard, the development towards Industry 4.0 was advanced. Each new version represents a small step along this path. However, the release now published represents a real milestone. The “calculation” is simple: because the products can be described in even greater detail, a correspondingly detailed engineering process is also possible.